|

|

||

Comparison of U-position-level Data Center Assets Management Product |

||

|

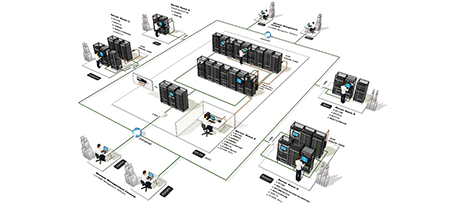

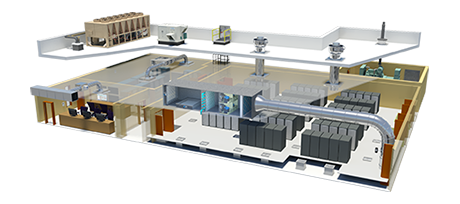

Automated data center assets management system is a hot market recently, there are only several companies have the product for U-position-level data center assets management. These companies include Digitalor, company R, company M, Company xB and Company WH. How to choose between these products? Now let’s analyze them from the perspective of reliability and lifecycle cost. You could also download the detailed Comparison Matrix from our website. Company R is the first company developed the U-position-level data center assets management system, its product(Pic. 1) read the server information via the electric connection between the AMS and AMT. Operation staff can plug the AMT to the corresponding AMS, then the AMS will send the location information to the database. However, the electric connector has inherent problem. Plugging action will slowly damage the connector, lead to unstable connection, besides, the connector could be damaged by static electricity and oxidation. These problems determined the durability of the product is below user’s expectation. The lifespan of a data center is usually over 10 years, so users want the durability to reach 10 years. Company xB’s product(Pic. 2) is very similar to company R’s, the major difference is the connector only, company R’s connector is like a snap button, while company xB’s is like a USB connector. They have the same problem, so skip the repeated content here. |

||

| Conclusion: High OpEx. | ||

|

|

|

| Pic 1. Company R's product | Pic 2. Company xB’s product | |

|

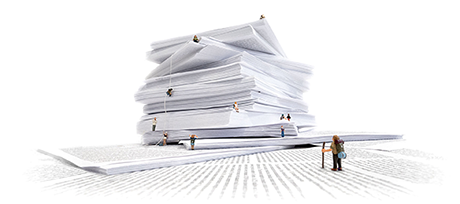

Then let’s talk about company M’s product(Pic. 3), it adopts the traditional RFID technology, each server will be attached with a RFID tag, then use the RFID reader at each U position to read the tag, so which U position the server is at will be known according to the unique ID of the RFID reader. This solution’s critical problem is bad reliability. The RF signal will interfere each other, especially when being near, and the RF antenna will consume itself slowly, the effective reading range will change accordingly, it’s extremely complex to adjust every antenna and every tag during the lifecycle. Because of the high cost for adjustment, and bad stability, this solution cannot be deployed in big scale. Company WH’s product(Pic. 4) is similar to Company M's, so no more repeat here. |

||

| Conclusion: High OpEx, low reliability. | ||

|

|

|

| Pic 3. Company M’s product | Pic 4. Company WH’s product | |

|

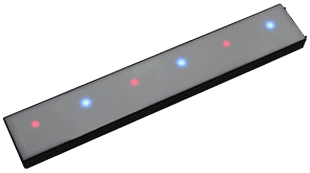

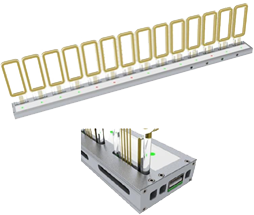

Until 2015, Digitalor learned the experience of other companies in this industry, invented MC-RFID technology, it solved all the problems others met. MC-RFID is not the same as traditional RFID, it’s of triggered working mode. It works only when there is assets change happens, so the RF interference and antenna consumption are resolved. MC-RFID is not electric connection, so do not have the problem of connector maintenance. The durability of Digitalor’s product(Pic. 5) is over 10 years. |

||

| Conclusion: Low OpEx, high reliability. | ||

|

|

||

|

Pic 5. Digitalor’s product |

||

|

After Digitalor’s product went to the market, many data center experts for companies like Schneider-electric (APC), Emerson Network Power, IBM, ZTE did in-depth research of Digitalor’s product. They all express the appreciation for this new technology, and most of them start using or integrating it in their solutions. |

||

My Account

- (+668) 3055.5503

- This email address is being protected from spambots. You need JavaScript enabled to view it.